Faced with the obligation to reduce CO2 emissions by 2050, the shipping industry is gradually coming round to the idea of new propulsion solutions, in particular wind-assisted systems. It’s an environment in which VPLP Design’s expertise, leveraged from experience gained in offshore racing, is already commanding attention from shipowners, an example being the Canopée project. Interview with Marc Van Peteghem, cofounder of the firm.

What aroused VPLP’s interest in decarbonization and hybridization, developing solutions that utilize wind power and engines?

In order to answer that question, we need to look back 200 years when the first steam engines were being installed on sailing ships. They couldn’t do away with the sails completely because the energy density of coal was too modest. For transoceanic voyages, a ship without sails would have had to carry so much coal that there would have been little room left in the hold for cargo. So even then, hybrid propulsion was a key consideration. Fast forward two centuries, and the same thing is happening in today’s shipping industry, in the sense that the biofuels of the future, which everyone is champing at the bit for and which should be available in the next ten to fifteen years, will have a lower energy density than current fuels, so they will take up more space. Hybrid propulsion harnessing the wind makes sense. Even more so, given the issues relating to climate change and the additional twofold constraints of the International Maritime Organization (IMO) regulations aimed at halving CO2 emissions by 2050 and the carbon taxes which are currently being put in place. There’s also the increasing pressure from society and investors who want to see cleaner transport solutions. As a result, certain specialists suggest that 40,000 boats need to be built over the next ten years if we want to comply with all these constraints.

Is this the firm’s standpoint?

Yes. The issue facing architects is how to install new propulsion systems on boats which were never designed to work in that way. Today, certain shipowners are reluctant to invest huge sums in existing vessels, deciding instead to inject just enough money to ensure compliance with environmental regulations. Others focus on building new boats, which is a completely different ballgame because the aim there is to get the best overall efficiency over the long term, integrating the concept of hybridization right from the outset. From this point of view, VPLP has a legitimate contribution to make thanks to the tools we’ve developed for the racing world, in particular the wingsail concept we launched on the trimaran USA 17, Oracle’s bid for the 2010 America’s Cup. In addition to being in a position to propose hybrid solutions for vessels, we can also work on finding the best possible balance between aerodynamic and hydrodynamic considerations, just as we do for racing.

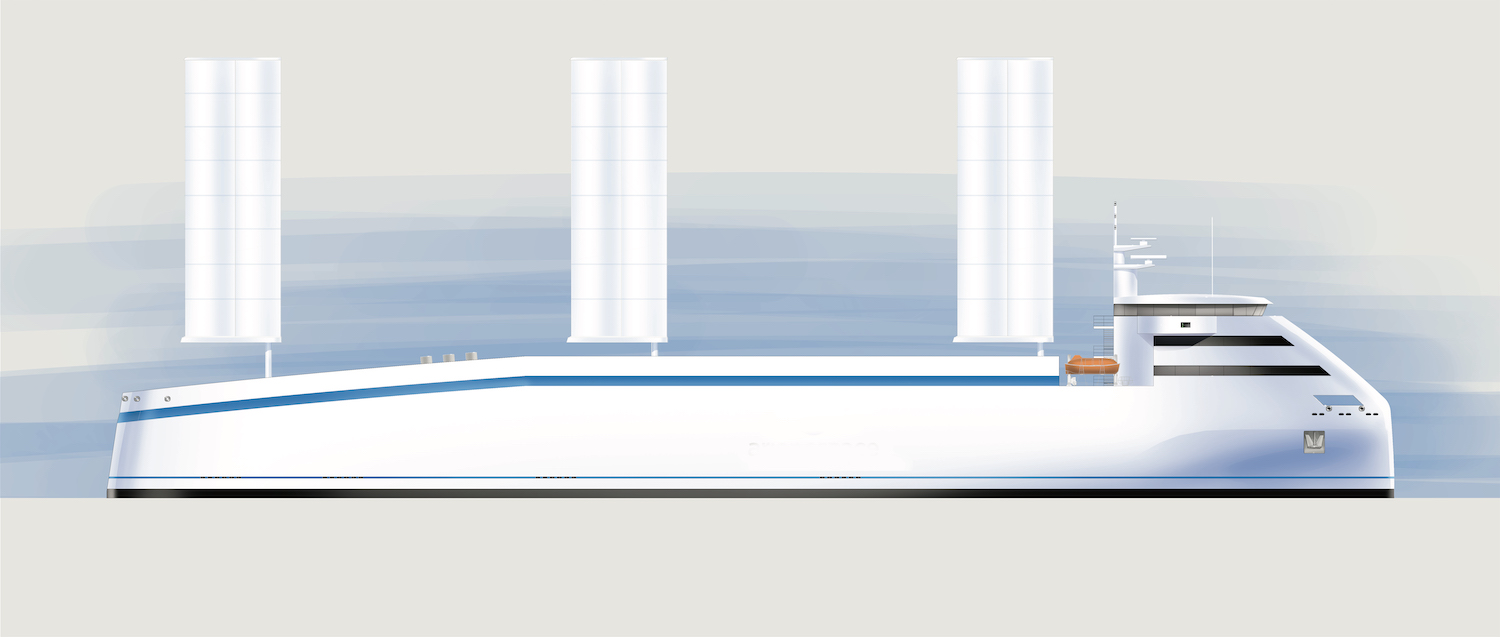

You have already entered a very practical phase since working on Canopée, a hybrid vessel featuring four wingsails which is designed to carry parts of the Ariane rocket from Europe to French Guiana. In concrete terms, what did your technological input involve?

We took great care over the aerodynamics, especially the forecastle which was designed so as to facilitate airflow and the integration of the wingsails. We also spent a lot of time working on the ship’s fore-and-aft equilibrium. It’s important to understand that the overall aerodynamic trim is not necessarily derived from the best trim for each individual wingsail, but instead of the vessel in its entirety. You have to be careful to avoid inducing too much drift or helm angle. And from a hydrodynamic viewpoint, we did a lot of research on the fact that, given the propulsive contribution of the wingsails, the propeller powered by the engines is already turning in a flow which is moving forward, which meant that we had to look into the settings of the propeller. Speed is another subject that we had to consider, given that fully automated and optimized wingsails when used in conjunction with a conventional propulsion system reduce CO2 emissions by 30% at low speed and by 20% at full speed. If we want to consume less and less fuel, we need to either reduce speed or develop more efficient sailing rigs.

Do you have the impression that the shipping industry is changing and that your proposals are resonating with stakeholders?

Yes, a very strong one. We can feel that the industry is undergoing a change. Nobody is really expecting anything of us, but then nobody thought of integrating wingsail propulsion a few years ago! Change will come at different speeds, but I hope the Canopée project will be a defining moment in the history of maritime transport, because that would mean our little team of naval architects will have also managed to make a difference. We are also working on small freighters and passenger ferries, because I believe we should be reducing the size of boats. Very big boats are difficult to decarbonize.